WKM 370D Series Ball Valves

The Cameron WKM 370D Series ball valves satisfy a wide range of ANSI and API Spec 6D applications. Engineered for heavy-duty, reduced-maintenance performance and manufactured in a variety of body and seal materials, WKM 370D Series valves are commonly selected for many specialized applications such as gas distribution, gas transmission, oilfield production, and industrial applications

WKM 320 Series Ball Valves

Previously, manufacturers have had to use a vented ball configuration to avoid trapping cavity pressure, limiting the valve to work in only one direction.

The WKM 320 Series floating ball valve features a patent-pending seat that enables internal cavity relief while maintaining bidirectional sealing capability.

Advantages

Bidirectional sealing capability

Built-in cavity relief to prevent excess pressure build-up around the ball

Lower break-to-open torque for reduced actuation requirement and easier operation

In every trim, WKM 320 Series valves include NACE compliance, fugitive-emissions capabilities, and fire-test certification to API Spec 607 7th Ed.

WKM 310F Floating Ball Valve

The Cameron WKM Model 310F floating ball valve satisfies a wide range of applications. Engineered for heavy-duty, reduced-maintenance performance, the WKM 310F ball valve is commonly selected for a variety of applications in a wide range of industries. This includes numerous applications in the chemical and petrochemical industry.

Extreme temperatures

Special high-temperature trims are available for service up to 600 degF [316 degC]. This trim is good for steam service, hot oil, heat transfer fluids, boiler feed water, and similar applications.

Low-temperature-service standard trims accommodate temperatures to –50 degF [–29 degC].

WKM 310C5 Floating Ball Valve

The Cameron WKM 310C5 floating ball valve satisfies a wide range of applications. Engineered for heavy-duty, reduced-maintenance performance, and available in a variety of materials, the WKM 310C5 ball valve is preferred for use in critical applications.

Slurries and abrasive ladings

Seat trim 92H has been developed to handle highly abrasive slurries such as lime mud, catalysts, and coal slurries. Using 316 stainless steel as a base, the ball and seats are coated with an abrasion-resistant skin of chromium oxide and are lapped together to form a matched metal-to-metal sealing set. The coating has a hardness of Vickers 1200 to 1400, which is approximately equivalent to Rockwell C 72-74. Valves trimmed for this service can be rated up to 600 degF [316 degC].

Sour oil and gas service

DynaSeal pressure seals have served for years in gathering lines, manifolds, and field processing units in sour oil and gas fields. They can be trimmed to conform with NACE MR0175.

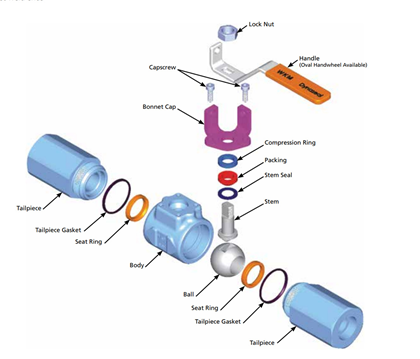

WKM 210A Floating Ball Valve

The Cameron WKM Model 210A floating ball valve is a two-piece design with a ductile iron body and tailpiece. This economical valve includes many of the premium design features found in the WKM carbon steel 310C and 310F ball valves. This valve primarily is used in the oilfield market, typically chosen for the following applications:

Production wing valves on low-pressure gas wells

Production flowlines

Production gathering systems for water, oil, and gas

Gas blowdown service

Tank batteries for storage or production

Frac water tanks